Honeywell Electronic Materials

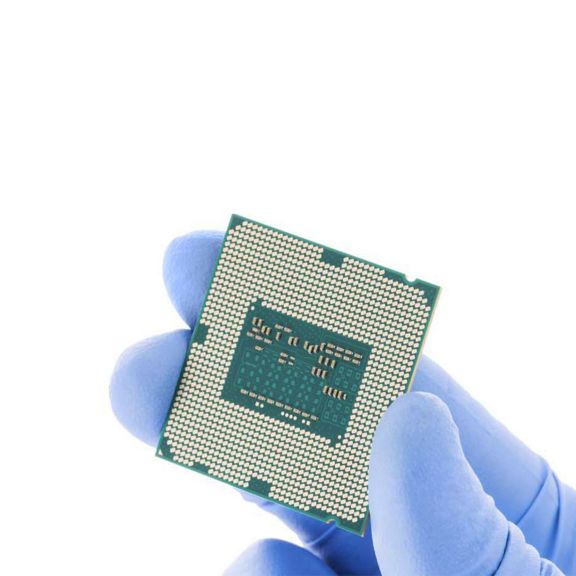

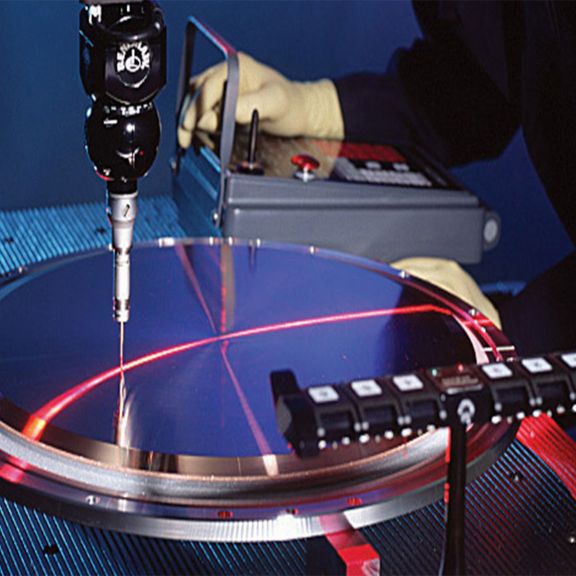

Maintain your competitive edge with Honeywell Electronic Materials’ sputtering targets for the semiconductor industry, our pioneering spin on glass (SOG) microelectronic polymer technology, Low Alpha phase change material such as Honeywell T11, HCL chemicals, and more.

As part of Honeywell, we share in the strength, resources and best practices of one of the world’s leading corporations. We invest in innovation and hold nearly 400 granted and pending patents. Our three major centers dedicated to research and development are in Sunnyvale, California; Spokane, Washington; and Shanghai, China. We are committed to evolving our quality disciplines to ensure that we exceed customer requirements.

Product Finder

Start your search with category name, product name, part number, etc.